Created by nature, silk is a material embracing a fascinating combination of properties and functions:

Silk is not only highly durable, but light in weight, breathable and furthermost – biodegradable.

We believe that nature’s continued evolutionary skill should not be left unexploited. Therefore, we specialize in the isolation and further processing of proteins extracted from natural silk into an ample variety of products while benefiting from unlimited possibilities concerning further refinement and application. Aside from its natural origin, the capacity of adjustable biodegradation eminently substantiates the striving role silk protein currently inherits in the working field of biomedical engineering. Due to its outstanding versatility, the employment of silk is not limited exclusively to the biomedical field: It may be incorporated in a manifold range of various other applications!

Silk fibroin – a protein with striking potential

Biomedical engineering implies the utilization and incorporation of biomaterial in the production process of medical implants. These implants are intended and designed to support the regeneration of soft or bony tissue by providing a growth-guiding scaffold-like structure mimicking the properties of the to-be-replaced tissue. While subsiding in the human body due to continuous degradation, which in turn is encouraged by the metabolic activity of the surrounding flora, the implant itself is gradually replaced by autologous healthy tissue over a distinct amount of time. Nowadays, the application of biomaterials ranges from orthopedics to dermatology, also including applied dentistry, where biomaterials serve as barrier membranes, which are predominantly used in modern guided bone regeneration (GBR) therapy.

The main component of natural silk is a protein, namely fibroin. Its bountiful favorable properties warrant fibroin a material of choice to be incorporated in the modern medical product palette. The extraction of fibroin from silk solution and its further processing into a final medical implant serves a handful of complex demands, including: a broad dimension of mechanical properties ranging from hard to soft firmness, structural variability including compact to porous forms and outermost flexible degradation properties enabling either short or prolonged perseverance of the implant in the human body. Moreover, ethical and religious concerns arriving from the implementation of allo- or xenogenic materials in the medical field may be successfully conquered by natural silk fibroin, which particularly illustrates why silk is currently emerging as a highly appreciated medical alternative for numerous patients worldwide.

Bombyx mori – the domestic silkworm, also known as the larva of the domestic silkmoth, functions as the primary provider of silk. As the larvae enter the pupal phase of their lifecycle, they enclose themselves in a cocoon made up of raw silk produced by the salivary glands. Silk fibroin is then harvested from the cocoon throughout an environmentally friendly and cost-effective isolation process without the use of potentially harmful solvents. The thus obtained protein solution builds the backbone of our production chain: Further processing then allows for transformation of fibroin into different shapes and functions, which in turn can be incorporated in advanced state-of-the-art product solutions in the field of biomedical engineering.

Fibroin based hydrogels exhibit high water contents and adjustable rheological behavior, hence enabling the bioengineered production of extracellular matrix templates. These templates inherit almost identical properties to their native counterparts, especially regarding structural and functional hallmarks. Fibroin hydrogels are therefore excellently suitable candidates for application in 3D cell cultures and tissue engineering. They are also handy for use in the widespread pharma- and cosmetics industry.

Fibroin based, sponge-like structures exhibit a self-expanding demeanor and may be used in a variety of biomedical applications, including hard and soft tissue regeneration in surgery and dentistry. Their flexibility enables the access of cavities and defects which may not be readily or easily accessible throughout a surgical procedure. In addition, the functionalization of fibroin sponges with respect to their surgical intention, for example via inclusion of growth factors or styptic substances reinforces tissue regeneration and diminishes peri- and postoperative blood loss. The porosity of the sponges ranges from micro- to macroporous and may be determined throughout the production process.

When introducing gas-generating components into the production process of fibroin solution, this results in the fabrication of dimensionally stable fibroin foams. Rapid and extensive spray application of drug loaded fibroin foams may permit easy and effective treatment of large, life-threatening wounds. Furthermore, fibroin foams may be utilized in aesthetic surgery for temporary shaping, contouring and the replenishment of congenital and acquired soft tissue defects.

Our unique casting process permits the production of either flat or curved transparent fibroin films with variable thicknesses. Our films flaunt with extended mechanical durability while maintaining outermost flexibility. Fibroin films may be applied in maxillofacial and orthopedic surgery or be utilized as edible coatings in the food industry. They might even be used as the new face mask in your habitual early-morning skin care routine!

The process of spinning facilitates the production of non-woven fibroin based textiles. Compact textile structures prevent cellular ingrowth and are therefore recognized as promising candidates in the area of guided bone regeneration therapy. Fiber diameter and textile density are easily influenced by different processing measures and play an important role for guided cell growth in humans and in animals. In addition, spinning of fibroin fiber allows for the manufacturing of vessel grafts, including vascular prostheses and patches.

If treated in a particular manner, fibroin exhibits adhesive properties. It may therefore be applied as a tissue glue in order to economically, efficiently and permanently close dermal wound lesions or maintain other tissues that have been subjected to damage. The removal of suture material becomes obsolete, as fibroin degrades over time while simultaneously allowing for the concomitant formation of new tissue.

FibroVision!

We specialize in the isolation and further processing of natural silk proteins derived from the cocoon of the domestic silkworm. Seeking constant technological progress, we are always eager towards exploring new fields of silky application: If natural silk could be the solution to your problem, we are your partner in crime!

Do you want to learn more about silk proteins?

We are looking forward to exciting cooperations in industry and academia!

The company

Professionals in material development, material sciences, and medical technology

Fibrothelium is a technology start-up business derived from the RWTH university, located in Aachen, Germany. We rely on vast experience in the fields of material development and science while focusing mainly on biomedical engineering. We encourage and rely on broad interdisciplinarity – consistently working together as a dynamic and determined team. Our core expertise consists of producing protein solutions extracted from natural silk, strictly omitting toxic solvents while maintaining low process costs and remaining thoroughly environmentally friendly.

Our team

Each product resembles the spirit of the working people: Our team is passionate about bioinspired product solutions – whether its development, manufacturing, regulatory affairs or marketing! We equally share our fascination for mother earth’s creative genius and therefore dedicate ourselves to the production of unique high-end, eco-friendly biomedical products comprised of readily available, natural silk.

Key Opinion Leader for Fibrothelium

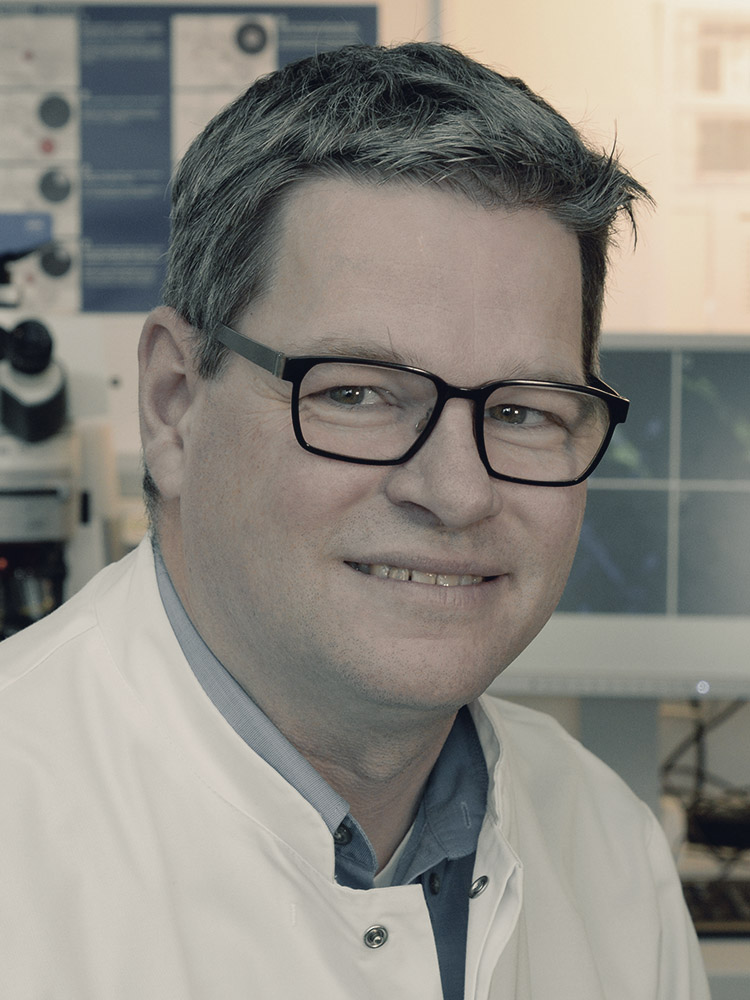

Prof. Dr. med. Stefan Jockenhövel

AME – Applied Medical Engineering

Helmholtz Institute Aachen

‚Nature is an excellent teacher when it comes to preserving and restoring biological functions in the human organism. Fibrothelium thoroughly embodies this idea: Carefully observing and studying your surroundings is essential for cutting-edge next-generation medicine!‘

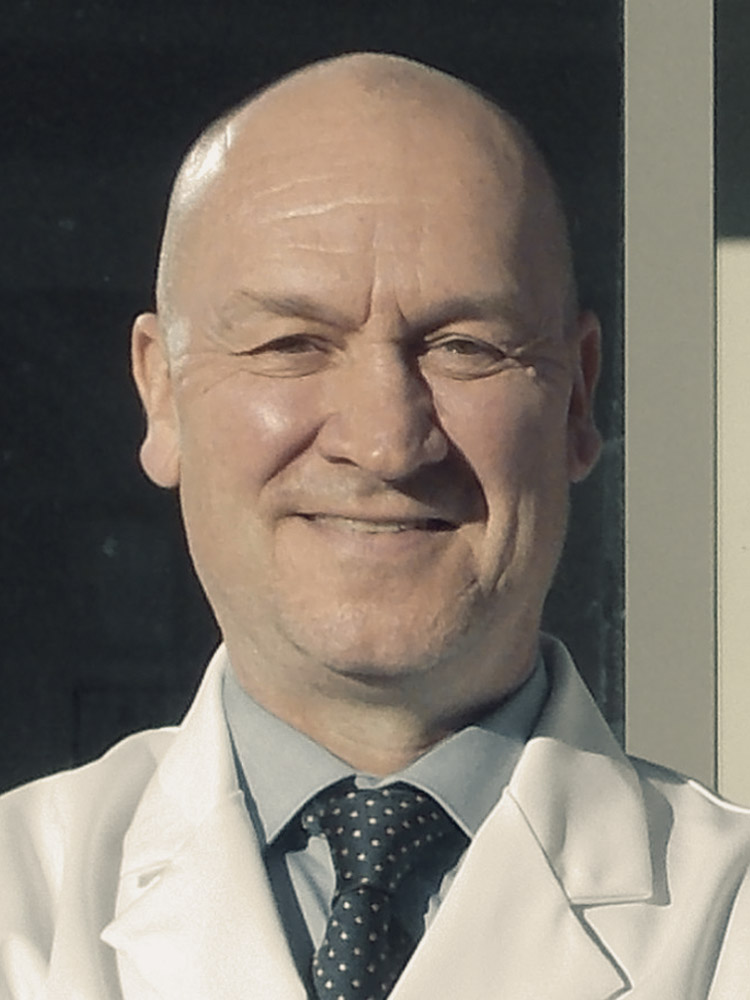

Dr. med. Jochen Salber

Head of the Department of Experimental Surgery

Knappschaftskrankenhaus Bochum GmbH

‚In the surgery of the future, tissue-compatible and absorbable materials will play an increasingly important role. The aim will no longer be just to repair, but to help the patient’s body to regenerate structurally and functionally after defect reconstruction. As a versatile biopolymer material the silk protein fibroin has enormous potential for application in surgical reconstruction!‘

Partners and patrons

Research projects enjoying public funding

FibroGraft

Composite implants designed for tissue regeneration:

What potential does silk fibroin bear?

The project focusses on the fabrication of fibroin based composite scaffolds. Our goal is the development of a production process which allows for the fabrication of elaborate carrier structures derived from liquid fibroin solution. These structures may include porous, fibrous and/or gel-like components. Our aim is the reinforcement of targeted tissue formation via introducing biomedical tissue engineered scaffolds in combination with stem cell therapy.

This project appreciates funding by the European Regional Development Fund (ERDF).

FibroXpand

The development of a manufacturing process comprising silk fibroin:

Porous, biodegradable and biocompatible surgical tissue replacement for hard and soft tissue defects

The project focusses on the development of self-expanding, fibroin based materials which may be applied as soft or hard tissue replacement therapy in surgery. The incorporation of biological functionalization into the production process may allow for tailored bioactivity of the manufactured scaffolds with respect to their clinical application and surgical indication.

This project appreciates funding by the Federal Ministry for Economic Affairs and Energy.

Our network

Our success strongly relies on the cooperation with our industrial and academic partners.

We are more than grateful to be supported by a strong network of intellectual professionals!

We are always looking forward to new fruitful cooperations and exciting ideas:

Please don’t hesitate to reach out and contact us!